Amanda Rodrigues de Souza

Coordenadora de P&D da Gerdau Florestal

OpCP71

A importância da qualidade na produtividade

A qualidade é fundamental para garantir a produtividade das florestas e, consequentemente, a competitividade das empresas do setor florestal. Existem muitas definições para o termo qualidade, porém, em sentido amplo, significa modelo de gerenciamento que busca a eficiência e a eficácia organizacionais.

Inicialmente, a qualidade foi considerada um cumprimento de exigências de normas e certificações. Contudo, a ampliação do seu uso nas atividades florestais brasileiras ocorreu devido à evolução da silvicultura, à ampliação dos investimentos florestais e ao crescimento da economia no País, em razão da necessidade de as empresas serem mais competitivas e de terem sido forçadas a adotar modelos de controle e gestão.

A visão sobre o conceito e a aplicabilidade da qualidade evoluiu, sendo, em um primeiro momento, tratado com abordagem corretiva, com foco apenas na necessidade de garantir o cumprimento das recomendações de manejo. Em seguida, observamos, além do cumprimento do planejado, o interesse de os controles funcionarem de forma preventiva, com oportunidades de mudanças e ganhos.

Na Gerdau, as análises de qualidade iniciaram nas operações silviculturais. E, atualmente, está presente em todas as nossas etapas de produção e tem apresentado diversos benefícios nos processos. Essas análises possibilitam a identificação de não conformidades dos processos e direciona as causas raízes dos problemas que devemos tratar.

Em nosso cotidiano, implantamos o método do PDCA em nossas florestas, no qual: o “Planejamento” é feito sobre quais análises e quando elas serão realizadas, com identificação do problema e análise do processo; “Executar” são os monitoramentos de qualidade; “Checar” é verificar se a execução está de acordo com o que foi planejado e “Agir” consiste na padronização e na implementação de soluções – completando, assim, o ciclo.

O conceito de controle de qualidade adotado foi desenvolvido conjuntamente com as áreas operacionais, de forma multidisciplinar. O processo é dividido em diferentes níveis. O primeiro nível é denominado autocontrole, sendo realizado na execução das atividades florestais pela própria equipe operacional.

O segundo nível consiste em auditorias realizadas nas atividades florestais por uma equipe específica do setor de qualidade, onde são verificados os índices de conformidade dos parâmetros preestabelecidos. O terceiro nível engloba as análises e os comparativos entre o primeiro e o segundo nível e as informações da performance da floresta.

O segundo nível consiste em auditorias realizadas nas atividades florestais por uma equipe específica do setor de qualidade, onde são verificados os índices de conformidade dos parâmetros preestabelecidos. O terceiro nível engloba as análises e os comparativos entre o primeiro e o segundo nível e as informações da performance da floresta.Com isso, conseguimos promover o trabalho entre equipes, analisar os desvios, tratar as falhas, estabelecer metas, facilitar a tomada de decisão, solucionar problemas com eficácia e agilidade, padronizar processos, proporcionar maior desempenho no processo e possibilitar redução de custos.

As tratativas e oportunidades de melhorias precisam ser discutidas, regularmente, com os clientes, para aprimoramento contínuo do processo. Contudo, para as empresas florestais que ainda não iniciaram as análises de qualidade em seus processos, é importante a celeridade, apesar das dificuldades de implantação, pois, mesmo que, algumas vezes, possam ser pouco representativas, elas possibilitarão identificar não conformidades que possam impactar negativamente o processo.

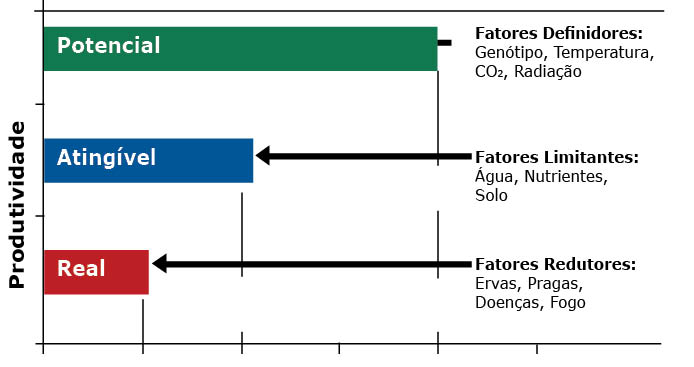

Em meio a um cenário competitivo de estratégias em busca da máxima produtividade florestal, estamos investindo na modernização florestal, adotando a qualidade como ferramenta rotineira em nossas operações, com mensurações e gerenciamento de parâmetros para que a produtividade atingível seja realidade, cercando os fatores limitantes das nossas florestas.

É necessário combinar fatores como produtividade, rendimento, custo de produção, disponibilidade de recursos e manutenção das condições que tornam possível produzir dentro do que é o potencial produtivo de cada área florestal e adotar práticas de manejo com parâmetros de qualidade que possibilitem a produção sustentável.

Em relação aos desafios da qualidade no setor florestal, temos a necessidade de estruturação e padronização de metodologias, avanço de tecnologias e agilidade na solução de problemas. Nesse último caso, é preocupante, pois benchmarking realizado entre empresas florestais demonstra problemas comuns e com morosidade na implementação de soluções.

Outros aspectos que necessitam ser analisados de forma abrangente é a qualificação técnica do setor de qualidade, número de colaboradores destinados a essas funções e a rotatividade de colaboradores. Outro ponto que é divergente entre as empresas florestais é a autonomia que o setor de qualidade possui para propor melhorias e realizar intervenções nas operações.

Outros aspectos que necessitam ser analisados de forma abrangente é a qualificação técnica do setor de qualidade, número de colaboradores destinados a essas funções e a rotatividade de colaboradores. Outro ponto que é divergente entre as empresas florestais é a autonomia que o setor de qualidade possui para propor melhorias e realizar intervenções nas operações.Apesar da qualidade ser imprescindível para garantirmos a produtividade de nossas florestas e evoluções no entendimento dessa ferramenta serem notórias, esse assunto ainda precisa ser explorado e tratado com maior importância, como os demais indicadores de segurança, produção, custos e outros dessa magnitude. Uma das alternativas é a comunicação e a colaboração entre as empresas florestais para tratativas conjuntas com celeridade e assertividade.

E, finalmente, a preocupação em garantirmos a qualidade das nossas florestas neste momento de nova ampliação das áreas florestais no Brasil, com alto investimento em máquinas e equipamentos apropriados para as diferentes condições de relevo, testes para novas práticas operacionais e estudos sobre o desenvolvimento de materiais genéticos de alta produtividade que têm contribuído para a competitividade do setor florestal brasileiro.