Carlos Alberto Justo da Silva Jr.

Gerente-geral de Planejamento e Competitividade da Eldorado

OpCP75

A evolução de máquinas, processos e pessoas

O avanço tecnológico tem impulsionado o desenvolvimento das florestas plantadas brasileiras e revolucionado nossa forma de atuação, impulsionando a competitividade e sustentabilidade do setor. Notadamente, as tecnologias de monitoramento e telemetria das operações, comunicação e conectividade, inteligência artificial, avanços na mecanização das operações e capacitação das pessoas, se destacam como pilares fundamentais desse progresso.

A primordial função das lideranças de campo é de coordenar as equipes, entender seus desafios, superar as dificuldades e entregar resultados. Desta forma, acompanhar a produção e a produtividade são primordiais aos líderes em campo. Neste quesito vimos muita evolução nos últimos anos. Passamos pela digitalização dos apontamentos operacionais e transmissão destes, à geração de informações e painéis de acompanhamento e, vendo valor neste sentido, nos debruçamos ao esforço da telemetria, buscando ainda mais a assertividade das informações. Tudo objetivando encontrar os vazamentos de produção. E por fim, hoje idealizamos sistemas sensoriados de monitoramento autônomo ou remoto, que viabilizam o acompanhamento em tempo real das atividades, proporcionando uma gestão ainda mais eficaz.

Estes sistemas preconizam conectividade, que segue um grande desafio dada nossa atuação, em áreas dispersas e distantes. Já estivemos mais distantes de uma solução viável, que solucionaria a questão de transmissão de um volume importante de dados que hoje coletamos em campo e traz luz a uma grande demanda que não deve de nenhuma forma ser menosprezada nos dias atuais, que é o acesso a conexão dos dispositivos móveis das pessoas que operam no campo. Estas, sentem muito a exclusão do meio social, quando perdem o acesso ao Whatsapp ou mídias sociais. O mundo hoje se comunica desta forma, e, se não tratarmos isso como uma necessidade, perderemos as pessoas para os centros urbanos.

Paralelamente, vendo potencial no desenvolvimento das tecnologias baseadas em inteligência artificial (IA), buscamos soluções para adversidades conhecidas e arriscamos encontrar soluções para problemas ainda incógnitos, explorando a capacidade de processamento das máquinas além da competência humana.

Mesmo ainda distante de aplicações operacionais de larga escala, temos investido nesta área, com poucos, mas muito promissores resultados em análises preditivas e otimização de processos. Na Eldorado, designamos uma equipe dedicada ao tema, de forma transversal às áreas de resultado, da qual temos grandes expectativas de soluções disruptivas, enquanto, outro time busca ganhos em melhoria contínua.

A mecanização das operações, além da colheita florestal, persiste como grande desafio ao setor. Nossa escala é grande como setor produtivo, mas ainda pequena para os grandes fornecedores de máquinas, quando nos comparamos a outros setores. Carecemos de máquinas purpose built florestais. Encabeçando a fila está a tão sonhada plantadeira mecanizada, que mesmo avaliando os protótipos mais recentes, ainda demanda muito desenvolvimento para atender a necessária qualidade e produtividade das operações análogas semimecanizadas. Não obstante, investir neste desenvolvimento é primordial, mesmo que não tenhamos destarte custos tão competitivos nas operações mecanizadas.

No curto/médio prazo não teremos outra opção, dada a escassez de mão de obra rural e a expansão dos investimentos em florestas em áreas marginais, com baixa/baixíssima densidade demográfica. Para nós da Eldorado, o foco do conceito de “cabinização” é dar qualidade ao posto de trabalho e não necessariamente redução de custos com a operação mecanizada."

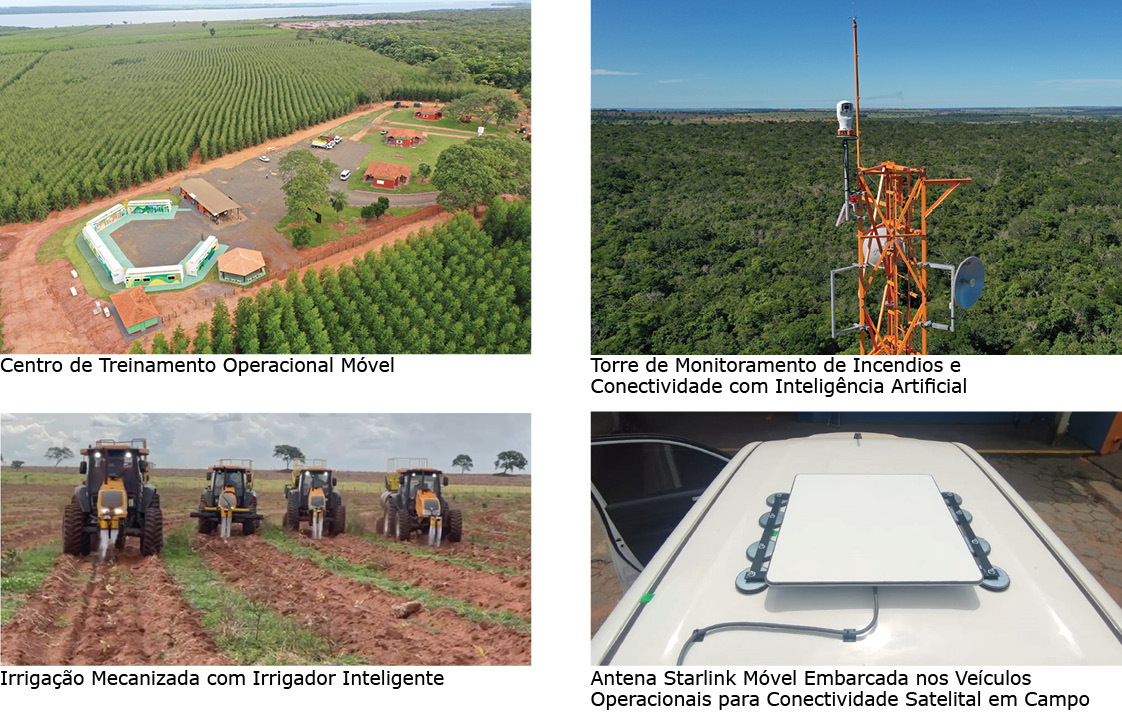

Como exemplo, na Eldorado, estamos substituindo a irrigação semimecanizada de plantio (1 tratorista + 5 ajudantes florestais) por uma irrigação mecanizada (irrigador no trator), onde aumentamos o número de máquinas (e tratoristas), mas reduzimos a exposição dos ajudantes, que caminham atrás dos tanques. Trabalhamos para igualar o custo da operação semimecanizada e ganhar com qualidade no posto de trabalho. Tenho muita certeza que seguindo no desenvolvimento da operação, vamos conseguir melhores produtividades e redução dos custos.

Provavelmente, em operações como o plantio, teremos que ainda amargar um custo maior para conseguir a “cabinização”, mas será a alavanca necessária para assegurar a possibilidade de expansão e mesmo da manutenção da produção. Não teremos pessoas dispostas a trabalhar atrás de um trator, “arrastando” uma matraca, em pleno sol, durante toda a jornada laboral. É preciso persistir no desenvolvimento operacional, mesmo que a duras penas. Tornar nossos postos de trabalho atrativos é fundamental para a sustentabilidade do negócio e um compromisso com a nossa gente.

Por fim, na base de todo o processo estão as pessoas. Precisamos colaborar, como setor, em formação e capacitação de pessoas. Não somente formar engenheiros florestais, mas também bons técnicos, operadores, mecânicos, eletricistas, borracheiros e outros. Quão mais tecnológicos estivermos no processo produtivo, mais isto é primordial. Quem sabe um dia possamos contar, como nos países nórdicos, com escolas públicas de formação florestal, e o papel das empresas ficar restrito em gerar a demanda. Por aqui, nossa realidade imprime a necessidade de encontrarmos outras soluções para este problema.

Em paralelo a formação, treinar as equipes é essencial para ganhar competitividade. Já nos primórdios da Segunda Revolução Industrial, Henry Ford dizia que “pior do que treinar um funcionário e ver ele sair, é não treinar o funcionário e ver ele ficar”. Ao fazê-lo não só estamos atuando na melhoria da produtividade e redução de custos, mas gerando oportunidades às pessoas. A dedicação e comprometimento dos colaboradores é incomparável quando os mesmos têm perspectiva de futuro.

Fazer um bom diagnóstico, ter objetivos claros, desenhar um currículo aplicado, sem “encher linguiça” com assuntos sem relevância prática (ensinar o padre a rezar missa), aplicar metodologias de ensino adequadas as funções específicas, medir os resultados obtidos e engajar os colaboradores e as lideranças, demonstrando o ganho conjunto no processo, são fundamentais para que o sucesso de um bom programa de treinamento.

A tecnologia também impulsionou novas ferramentas educacionais. A Eldorado recentemente inaugurou um Centro Móvel de Treinamento Florestal, que conta com containers totalmente adaptados e autossuficientes em termos de energia e água, permitindo de acordo com a necessidade, atender as demandas de treinamento junto a operação. A estrutura é composta de salas de aula, salas de hidráulica, pneumática, diagnósticos computadorizados e recuperação por eletrodeposição, salas com plataformas de realidade virtual e diversas máquinas para os treinamentos práticos. Este investimento está em linha com o projeto Trilha de Carreira, onde capacitamos nossos colaboradores às oportunidades internas de crescimento e os constantes desafios de ganhos de produtividade e eficiência operacional.

Em conclusão, o avanço tecnológico está presente em toda cadeia da floresta plantada brasileira e apresenta uma evolução significativa recente, integrando ferramentas de gestão de performance, sensoriamento e telemetria, conectividade, inteligência artificial, mecanização e tecnologias educacionais. Esses avanços impulsionam a competitividade do setor, consolidando o Brasil como referência global no manejo florestal avançado.