Eduardo Moré de Mattos e Arthur Vrechi

Diretor de Sustentabilidade e Diretor de Tecnologia da Geplant

OpCP71

Como avançar para uma visão mais ampla e sistêmica?

Historicamente, a qualidade florestal sempre foi associada à precisão na execução das prescrições silviculturais, medindo a habilidade da operação em cumprir os procedimentos, como se a distância entre linhas e covas está dentro de uma oscilação razoável, se a profundidade do preparo está dentro do limite, entre outros. Em resumo, o foco sempre foi maior no processo.

Contudo, como podemos inferir se essas ações e as prescrições estão garantindo que a floresta atinja a produtividade almejada? E, indo além, como determinamos qual o nível de produtividade a ser atingido? Aproveitemos o exemplo a seguir para ilustrar esses questionamentos.

Caso 1: A recomendação foi usar 1.111 árvores por hectare. Contudo, após o plantio, observou-se que havia, de fato, 1.250 árv/ha. Após 30 dias, a mortalidade apontada foi de 5%. Talhão reprovado no controle de qualidade.

Caso 1: A recomendação foi usar 1.111 árvores por hectare. Contudo, após o plantio, observou-se que havia, de fato, 1.250 árv/ha. Após 30 dias, a mortalidade apontada foi de 5%. Talhão reprovado no controle de qualidade.

Caso 2: A recomendação foi executada à risca, 1.111 árv/ha. Após 30 dias, apontou-se 0% de falhas. Excelência operacional constatada pelos mecanismos de aferição da qualidade.

Um talhão ao lado do outro, mesmo solo, mesmo clone, mesmas condições. Qual deles você escolheria para ser o campeão de produtividade? É claro que não podemos simplificar dessa forma processos complexos e que envolvem uma infinidade de fatores, como a disponibilidade de mudas, capacidade operacional, grau de profissionalização, pragas, déficit hídrico, etc. Mas a provocação é válida para refletir se estamos adotando os melhores critérios ao medir a qualidade florestal. Nosso intuito aqui é convidar o silvicultor a refletir sobre os processos e retomar as rédeas do pensamento florestal sobre como as árvores crescem, considerando a qualidade também sob a óptica do produto.

1. Qualidade do processo x Qualidade do produto: Entendemos que, tão ou mais importante que o processo, é a qualidade do produto, que, em nosso caso, é uma floresta bem formada, resiliente e que vai garantir uma produção eficiente de madeira ou outros produtos florestais.

Geralmente, partimos da premissa de que a excelência das operações vai garantir a qualidade do produto. Mas isso nem sempre é valido, e é justamente aí que estão as oportunidades de ganhos. Entretanto, sempre houve um desafio nessa questão. Tradicionalmente, o indicador utilizado para avaliar a qualidade do produto é a própria produtividade - o IMA (incremento médio anual). Ocorre que o IMA não é comparável em diferentes condições, ou seja, entre o processo (silvicultura) e o produto (madeira) está o ambiente de produção (solo, relevo, clima).

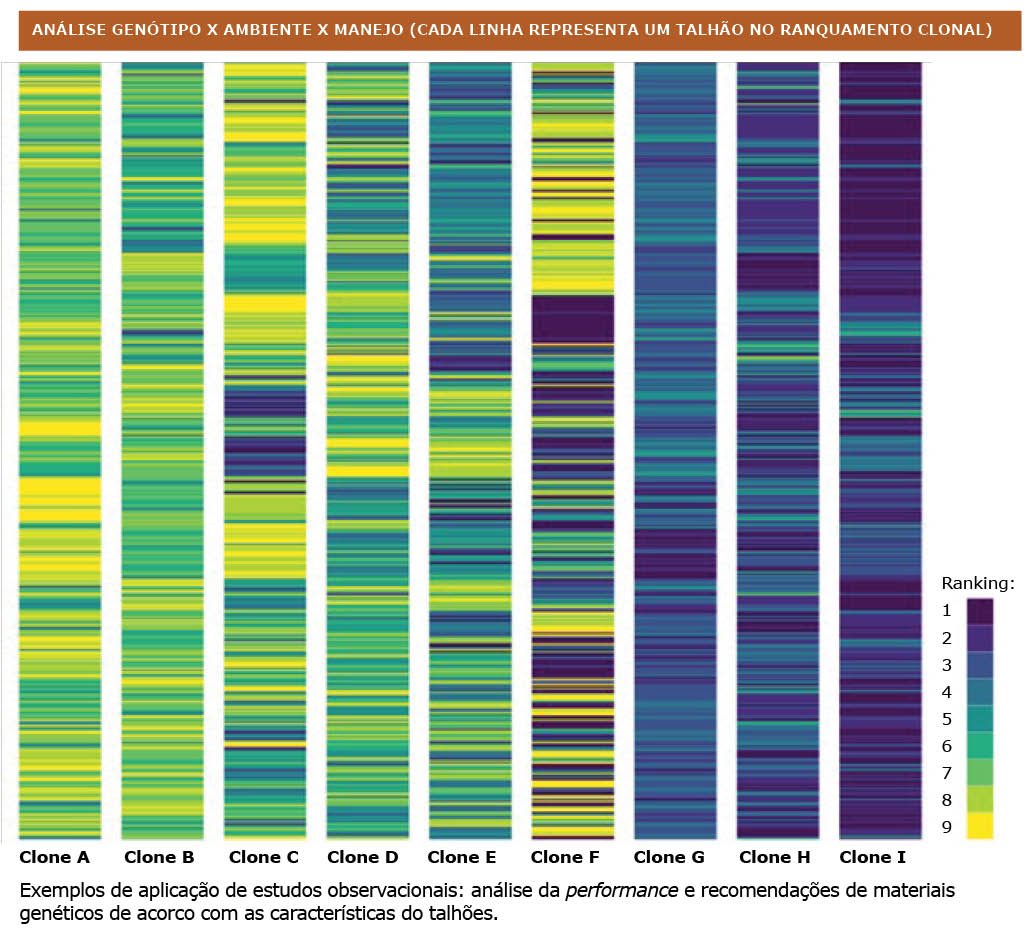

E é justamente a variação nos ambientes de produção que não permite inferências de causa e efeito entre processo e produto. A influência do ambiente de produção precisa ser considerada e ponderada. Uma solução é adotar um indicador de qualidade do produto relativo, ao invés de absoluto como o IMA. No entanto, relativizar o IMA passa, necessariamente, por um outro desafio: estabelecer um alvo de produtividade dinâmico (para cada talhão e rotação).

E é justamente a variação nos ambientes de produção que não permite inferências de causa e efeito entre processo e produto. A influência do ambiente de produção precisa ser considerada e ponderada. Uma solução é adotar um indicador de qualidade do produto relativo, ao invés de absoluto como o IMA. No entanto, relativizar o IMA passa, necessariamente, por um outro desafio: estabelecer um alvo de produtividade dinâmico (para cada talhão e rotação).

2. Produtividade-alvo (ou atingível): Estabelecer a produtividade-alvo é um desafio frequentemente encontrado em nossas conversas com profissionais do setor. Apesar de todos sentirmos as mudanças climáticas, ainda se segue adotando a produtividade da rotação anterior como guia. Em outros casos, o alvo é o máximo IMA já registrado no passado, opiniões empíricas de especialistas ou a famigerada produtividade da planilha, que ninguém sabe ao certo de onde surgiu, mas vem sempre antes do projeto se materializar e sobra para o silvicultor “fazer dar”.

2. Produtividade-alvo (ou atingível): Estabelecer a produtividade-alvo é um desafio frequentemente encontrado em nossas conversas com profissionais do setor. Apesar de todos sentirmos as mudanças climáticas, ainda se segue adotando a produtividade da rotação anterior como guia. Em outros casos, o alvo é o máximo IMA já registrado no passado, opiniões empíricas de especialistas ou a famigerada produtividade da planilha, que ninguém sabe ao certo de onde surgiu, mas vem sempre antes do projeto se materializar e sobra para o silvicultor “fazer dar”.

O fato é que é essencial existir um processo robusto, bem definido e dinâmico para determinar a produtividade-alvo do manejo florestal. E não somente para gerar um indicador relativo de qualidade do produto, como citamos, mas é a base de um planejamento florestal eficaz e responsável.

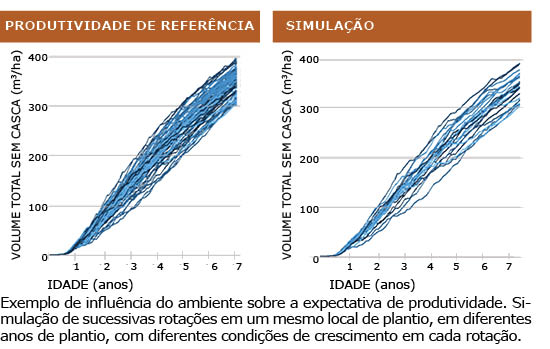

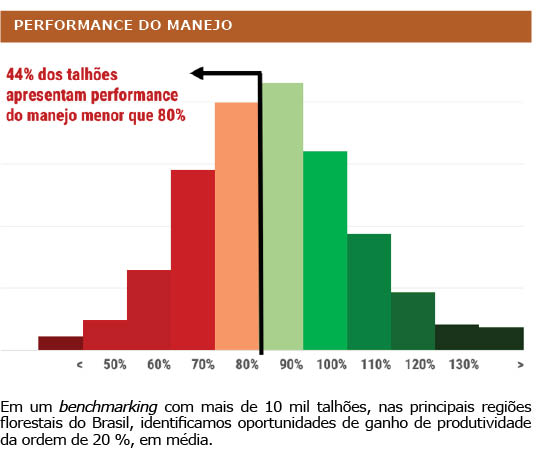

Aqui é interessante introduzir um conceito relevante, da teoria dos Yield Gaps: quando falamos em produção eficiente, precisamos avaliar a qualidade do produto não só pelo volume de madeira ou IMA, mas pela razão do quanto se produziu (Produtividade Real) em relação ao quanto se poderia produzir (Produtividade Atingível), dado o ambiente de produção e condições ideais de manejo.

Aqui é interessante introduzir um conceito relevante, da teoria dos Yield Gaps: quando falamos em produção eficiente, precisamos avaliar a qualidade do produto não só pelo volume de madeira ou IMA, mas pela razão do quanto se produziu (Produtividade Real) em relação ao quanto se poderia produzir (Produtividade Atingível), dado o ambiente de produção e condições ideais de manejo.

Nós batizamos essa razão de Performance do Manejo, um indicador que tem a vantagem de ser padronizado e permite comparar diferentes condições de clima, solo, idades, épocas de plantio etc. Em geral, temos encontrado oportunidades de ganho na ordem de 20% com ações para aumentar a performance do manejo.

Por mais que isso tudo pareça complexo, hoje temos ferramentas e bases de dados que nos permitem evoluir, graças a uma dedicada comunidade científica e avanços computacionais. Adotamos a teoria dos Yield Gaps, modelagem ecofisiológica, sensoriamento remoto, estatística, mapeamentos geográficos e tecnologia para resolver esse “quebra-cabeça”. Essas foram as ferramentas que escolhemos, mas não é a única abordagem, existem diversas outras.

3. Medir para gerenciar: Como já diz a máxima de gestão, o que não é medido não é gerenciado. Contudo, é essencial ter uma análise crítica dos controles de qualidade. Será que estamos medindo o que verdadeiramente importa? Quais desvios são realmente aceitáveis? Quais são os processos críticos e seus impactos na produtividade?

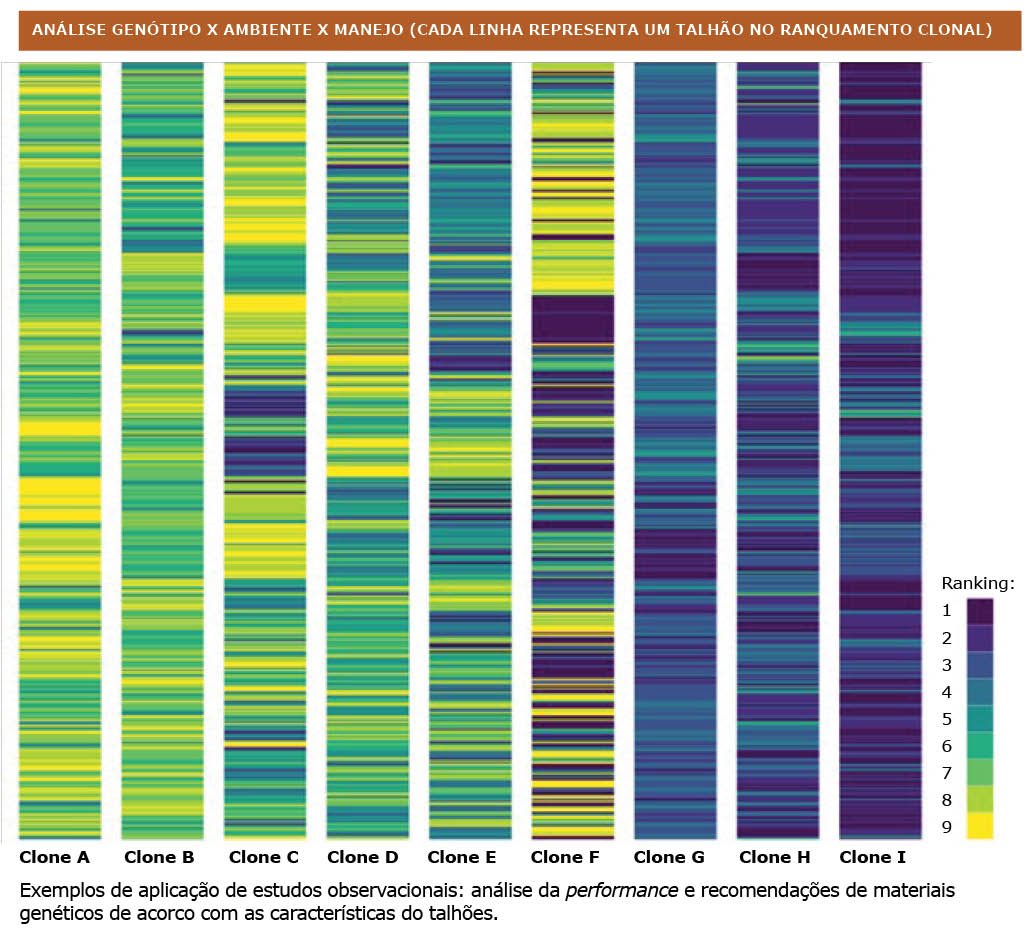

Esses questionamentos têm sido bastante comuns por onde andamos. Muitas dessas respostas podem estar nos estudos observacionais, analisando as relações entre processo e produto citadas anteriormente, afinal, os plantios são um verdadeiro laboratório a céu aberto. Isso nos permite explorar com mais plenitude nossas ricas bases de inventário florestal, identificar, quantificar e priorizar ações sobre os gaps de manejo e avançar em uma gestão da qualidade florestal mais ampla e sistêmica.

Esses questionamentos têm sido bastante comuns por onde andamos. Muitas dessas respostas podem estar nos estudos observacionais, analisando as relações entre processo e produto citadas anteriormente, afinal, os plantios são um verdadeiro laboratório a céu aberto. Isso nos permite explorar com mais plenitude nossas ricas bases de inventário florestal, identificar, quantificar e priorizar ações sobre os gaps de manejo e avançar em uma gestão da qualidade florestal mais ampla e sistêmica.

4. Autorregulação e melhoria contínua (a história da sopa): Constatar não conformidades no pós-operação é importante, mas possibilitar estratégias para sanar prejuízos de desvios, principalmente em operações que não permitem correções (o preparo de solo, por exemplo), deveria ser o foco. Hoje, existem soluções tecnológicas embarcadas que geram alertas e permitem ajustes em tempo real, para garantir o alinhamento de plantio, controle de dosagem, taxa de aplicação e sobreposição em pulverizações, entre outros.

Como aprendemos com um grande mestre do setor florestal: “A sopa poder ser bem temperada, preparada com os melhores ingredientes e pelo melhor cozinheiro do mundo, mas se ela for servida fria, será horrível!”. Ou seja, não basta medir e só depois constatar ou não a conformidade. Isso gera distanciamento e atrito entre as equipes operacionais (quem faz), de pesquisa, de planejamento (quem fala como faz) e de qualidade (quem afere o que foi feito). Para nós, o foco deveria ser muito maior em autorregulação e melhoria contínua do que em auditoria.

Outro aspecto importante são as relações na terceirização da silvicultura. É preciso pensar conjuntamente no investimento para melhorias e fortalecer relações de parceria. Acreditamos que, apenas quando há, de fato, a formação de times (e não de equipes), com foco no resultado da floresta, é que os melhores resultados se expressam. Por fim, é fácil concluir que a maior tecnologia a ser trabalhada para garantia da qualidade florestal se encontra nos aspectos humanos e nas suas relações de interdependência.