Sergio Lopes dos Santos

Coordenador de Inovação e Qualidade Florestal da Veracel

OpCP69

Um bom momento para a silvicultura

Coautoria: Italo Lima Nunes, Analista de Processos Florestais da área de Inovação e Qualidade da Veracel

O setor florestal brasileiro é um dos mais desenvolvidos do mundo, isso devido à sua alta produtividade, aos seus custos competitivos, aos avanços tecnológicos e às condições edafoclimáticas favoráveis à produção. A área de florestas plantadas para fins industriais no Brasil alcançou mais de 9,5 milhões de hectares, de acordo com a Indústria Brasileira de Árvores – IBÁ.

O setor florestal vem de uma crescente demanda de madeira, com a chegada de novos empreendimentos e a expansão de base florestal visando atender à produção fabril para os seus diversos fins. Essa escalada tem fomentado a busca pelo aumento da tecnologia nos processos, com o objetivo de alcançar maior mecanização das operações florestais, sinergia de processos e aumento da competitividade.

A capacidade de modernização de uma organização é reconhecida como um fator-chave para o crescimento sustentado, a viabilidade econômica, o aumento do bem-estar e o desenvolvimento da sociedade. E inclui a capacidade de entender e responder às mudanças nas condições de seu contexto, de buscar novas oportunidades e também de alavancar o conhecimento e a criatividade das pessoas dentro da organização, sempre em colaboração com as partes externas interessadas.

Apesar dos importantes avanços, que proporcionaram solidez ao setor nas últimas décadas, temos ainda alguns desafios a serem superados. Destacamos, aqui, alguns deles: o desenvolvimento da mecanização na silvicultura e da automação das operações, a busca por uma eficiente matriz energética nas operações, a gestão integrada das informações e o importante papel da liderança nesse contexto de modernização cultural e tecnológica.

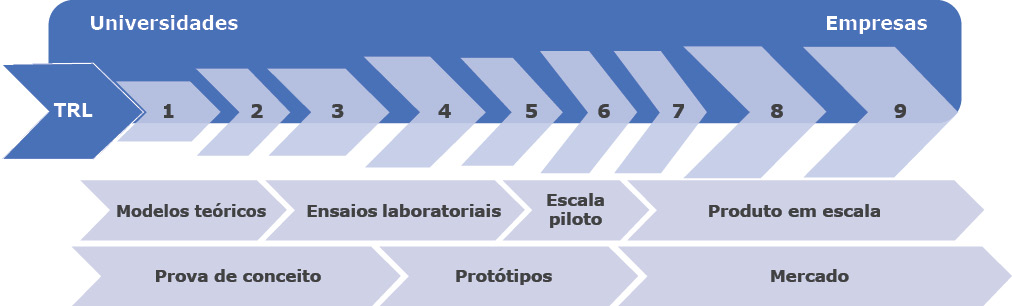

Em termos de mecanização das operações silviculturais, estamos em um bom momento, com importantes projetos em desenvolvimento e operacionalização de plantadeiras e irrigadores, com o envolvimento de relevantes empresas fabricantes, com expertise e capacidade técnica, financeira e gerencial para fornecer ao setor, em breve, excelentes soluções. Vale ressaltar também o importante papel das universidades e dos institutos de pesquisa nesses programas de desenvolvimento, por meio de grupos temáticos de trabalho.

O desafio consiste em aliar a qualidade do plantio, a eficiência, o custo competitivo e a adaptabilidade das máquinas nos diversos tipos de terrenos e condições, atendendo aos critérios específicos de plantio de cada empresa, em suas respectivas regiões. Outra tendência que se tem observado é o desenvolvimento da automação das operações florestais, como outros setores têm evoluído, a exemplo da mineração, com operações teleoperadas (autônomas ou semiautônomas), sobretudo no desenvolvimento de soluções tecnológicas visando levar segurança e produtividade a locais com alto risco de acidentes. Além das iniciativas dos grandes fabricantes de máquinas e implementos, algumas empresas nacionais têm se especializado no desenvolvimento dessas soluções.

Não podemos deixar de destacar a importante mudança da matriz energética das operações: motores mais eficientes, elétricos, híbridos, usando biocombustível, gás natural ou eletrificados, já são realidade nos pátios de madeira em diversas fábricas no Brasil. Na renovação das frotas operacionais, abre-se oportunidade para a mudança de matriz energética das máquinas, como escavadeiras, máquinas de preparo de solo e colheita florestal. Para o transporte de madeira, testes com caminhões elétricos têm demonstrado bons resultados em performance.

Essa mudança vem não só devido ao custo dos combustíveis, mas também está pautada na estratégia global visando à redução das emissões de carbono, tornando ainda mais sustentável o setor de florestas plantadas. Apesar da realidade de baixa cobertura de conectividade na totalidade das áreas florestais, o desenvolvimento de tecnologias de transmissão e apontamento traz melhorias técnicas e oportunidade para análise das operações florestais.

Portanto, o gerenciamento digital das operações com o uso de dados, integrando diferentes plataformas, permite que os gestores acessem, monitorem e segreguem dados, obtendo informações de qualidade para a tomada de decisão. Com isso, a eficiência da operação é elevada, uma vez que, quando de posse de informações de qualidade, os riscos das operações são minimizados ou se podem tomar decisões em menor tempo.

Portanto, o gerenciamento digital das operações com o uso de dados, integrando diferentes plataformas, permite que os gestores acessem, monitorem e segreguem dados, obtendo informações de qualidade para a tomada de decisão. Com isso, a eficiência da operação é elevada, uma vez que, quando de posse de informações de qualidade, os riscos das operações são minimizados ou se podem tomar decisões em menor tempo.

A utilização de redes de sensores em uma máquina florestal, conectados a um sistema de coleta de dados, permite medir diversas variáveis importantes para todo o processo. Nesse contexto, para concretizar tais ganhos operacionais, é necessário mais que um bom sistema: o conjunto entre sistema, usuário e análise dos dados é fundamental para o sucesso de qualquer tecnologia.

O treinamento e o aculturamento dos usuários formam um pilar fundamental para que dados de qualidade sejam integrados às bases dos sistemas de gestão. O monitoramento dessas informações, por meio de sistemas, auxilia as empresas com análises robustas, identificando novas necessidades, e pode aumentar a produtividade e gerar redução de custos. Tanto a telemetria quanto o apontamento eletrônico têm impactos positivos, reduzindo o tempo de resposta a diversos ofensores operacionais. Hoje, em diversas empresas, esses dados ficam englobados em centrais de controle e gerenciamento operacional.

O treinamento e o aculturamento dos usuários formam um pilar fundamental para que dados de qualidade sejam integrados às bases dos sistemas de gestão. O monitoramento dessas informações, por meio de sistemas, auxilia as empresas com análises robustas, identificando novas necessidades, e pode aumentar a produtividade e gerar redução de custos. Tanto a telemetria quanto o apontamento eletrônico têm impactos positivos, reduzindo o tempo de resposta a diversos ofensores operacionais. Hoje, em diversas empresas, esses dados ficam englobados em centrais de controle e gerenciamento operacional.