Jozébio Esteves Gomes

Coordenador de Competitividade e Projetos Florestais da Eldorado Brasil

OpCP73

A silvicultura do futuro é agora

The future is now – O Futuro é agora – do autor de Three-Box Solution, o professor Vijay Govindarajan retrata bem o momento em que a silvicultura mundial vem passando em termos de Transformação Digital. Sem deixar para trás a aptidão tecnológica, em desenvolvimento operacional de novas máquinas e equipamentos para mecanização florestal, a silvicultura também tem se mostrado como um dos grandes campos de oportunidades em inovações disruptivas que contribuem significativamente para o aumento da performance operacional em campo.

Essas inovações, hoje, congregam desde o uso de aplicativos e aplicações mobile, passando por sensoriamento remoto do acompanhamento do crescimento da floresta, e, até mesmo, com as soluções embarcadas em máquinas e equipamentos, as quais permitem a realização do monitoramento operacional em tempo real.

Estamos realmente em uma fase em que as operações assistidas nos permitem tomadas de decisões céleres, fazendo com que tenhamos a máxima extração da produtividade operacional em nossos processos de produção florestal.

Hoje podemos sensorear praticamente tudo no processo silvicultural, e tudo começa no planejamento, com poderosos softwares de otimização e ordenamento da produção florestal que permitem planejar com precisão a implantação das florestas e, até mesmo, o microplanejamento digital das atividades e operações florestais que serão realizadas para o sucesso do empreendimento.

Nesta etapa, também, temos uso de inúmeras tecnologias, começando pelo uso de Drones e VANTs – Veículos Aéreos Não Tripulados, que realizam os voos cadastrais autônomos para levantamentos dos parâmetros necessários a uma boa prática do uso do solo, respeitando as condições edáficas e topográficas, bem como os critérios ambientais. Veja a figura 1 no grupo de ilustrações.

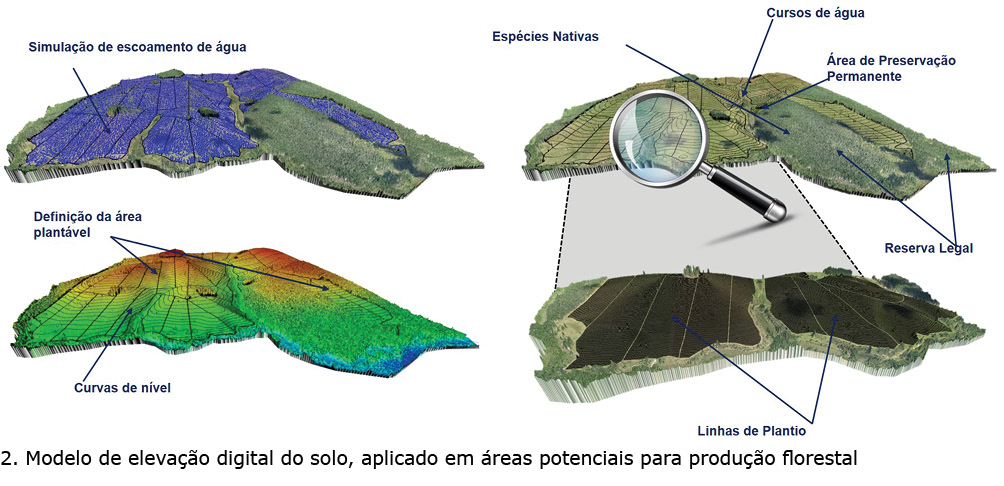

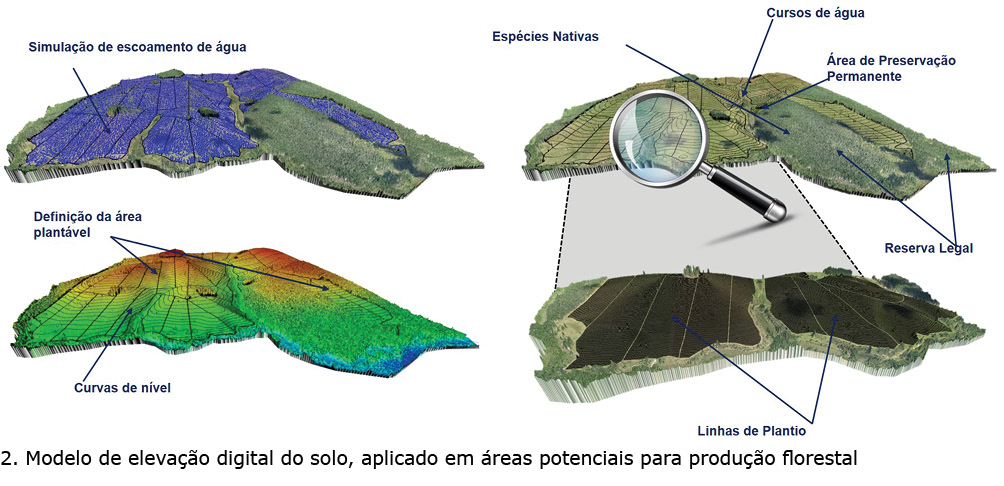

Com a coleta dessas imagens, é possível utilizar os modelos de elevação digital do solo, obtendo detalhes importantes, tais como, declividade, áreas de proteção ambiental, estradas, carreadores e, até mesmo, simular o escorrimento superficial das águas da chuva e a distribuição dos talhões de forma otimizada. Veja a figura 2 no grupo de ilustrações.

Essas inovações, hoje, congregam desde o uso de aplicativos e aplicações mobile, passando por sensoriamento remoto do acompanhamento do crescimento da floresta, e, até mesmo, com as soluções embarcadas em máquinas e equipamentos, as quais permitem a realização do monitoramento operacional em tempo real.

Estamos realmente em uma fase em que as operações assistidas nos permitem tomadas de decisões céleres, fazendo com que tenhamos a máxima extração da produtividade operacional em nossos processos de produção florestal.

Hoje podemos sensorear praticamente tudo no processo silvicultural, e tudo começa no planejamento, com poderosos softwares de otimização e ordenamento da produção florestal que permitem planejar com precisão a implantação das florestas e, até mesmo, o microplanejamento digital das atividades e operações florestais que serão realizadas para o sucesso do empreendimento.

Nesta etapa, também, temos uso de inúmeras tecnologias, começando pelo uso de Drones e VANTs – Veículos Aéreos Não Tripulados, que realizam os voos cadastrais autônomos para levantamentos dos parâmetros necessários a uma boa prática do uso do solo, respeitando as condições edáficas e topográficas, bem como os critérios ambientais. Veja a figura 1 no grupo de ilustrações.

Com a coleta dessas imagens, é possível utilizar os modelos de elevação digital do solo, obtendo detalhes importantes, tais como, declividade, áreas de proteção ambiental, estradas, carreadores e, até mesmo, simular o escorrimento superficial das águas da chuva e a distribuição dos talhões de forma otimizada. Veja a figura 2 no grupo de ilustrações.

De posse dessas informações, são definidas e plotadas as linhas de plantio, para que as operações de preparo do solo sejam realizadas com precisão, embarcando-as nos computadores de bordos das máquinas, as quais operam por meio de uso de pilotos automáticos orientadas por GPS – Sistemas de Precisão Geográficas, conectados em tempo real com satélites poderosos, conforme detalha a figura 3 no grupo de ilustrações.

Praticamente, todas as operações silviculturais hoje permitem ser apontadas digitalmente, seja utilizando um equipamento mobile, tais como smartphones e tablets, e, até mesmo, com soluções embarcadas mais robustas, tais como computadores de bordos altamente inteligentes.

A diferença é que, para esse segundo, é possível a obtenção de forma automática dos ciclos operacionais de produção, bem como do estado de máquina, informações essas muito importantes para o monitoramento em tempo real das atividades operacionais e tomadas de decisão baseadas em dados do presente e, também, predizer alguma falha que por ventura poderá acontecer com o equipamento em nível mecânico. Veja detalhes na figura 4.

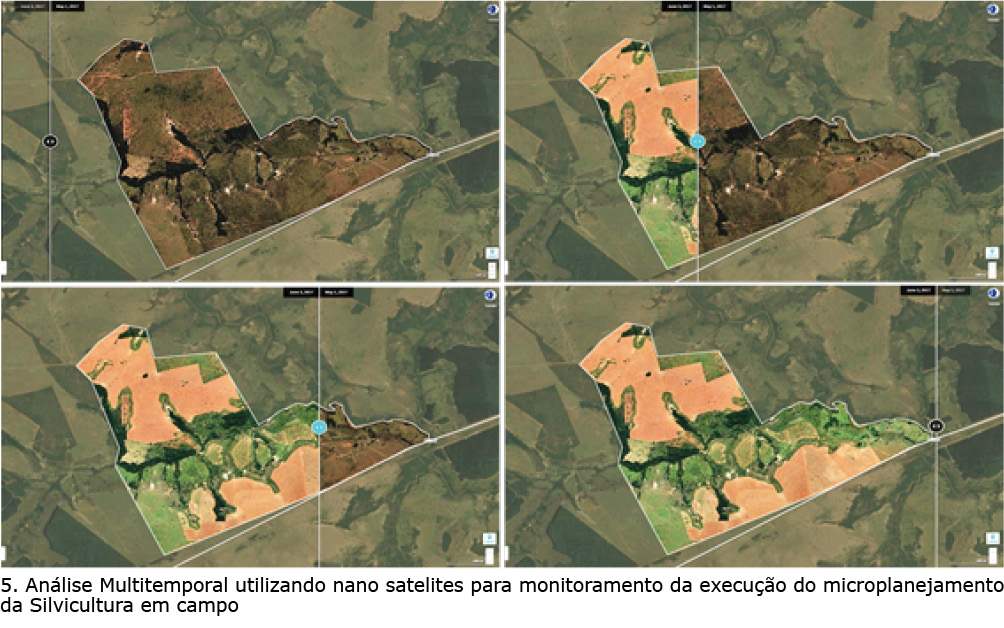

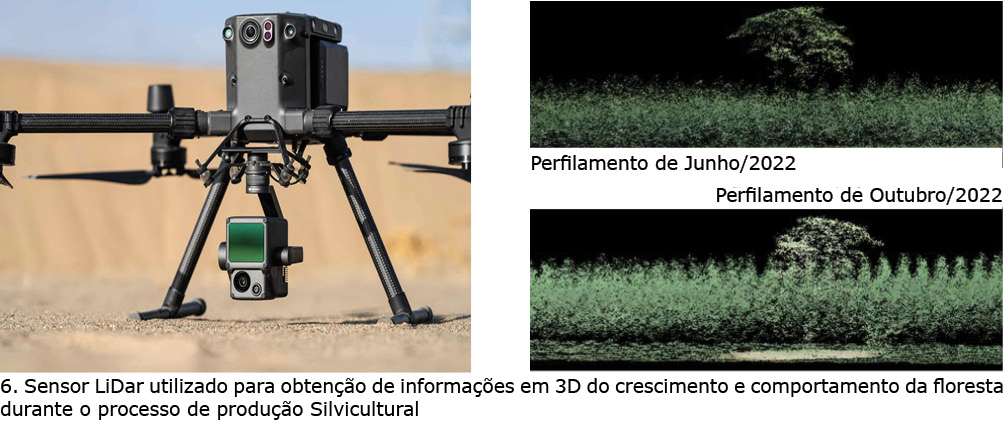

Outro ponto importante na prática silvicultural é o acompanhamento da evolução das operações em campo com base no que foi planejado no início. Para isso, hoje, é possível o emprego de tecnologias de análises multitemporais utilizando nano satélites. Isso permite o controle do realizado versus planejado, de forma segura e inteligente para obtenção da assertividade e acurácia na definição e na execução do microplanejamento operacional, conforme demonstra o conjunto de imagens da figura 5.

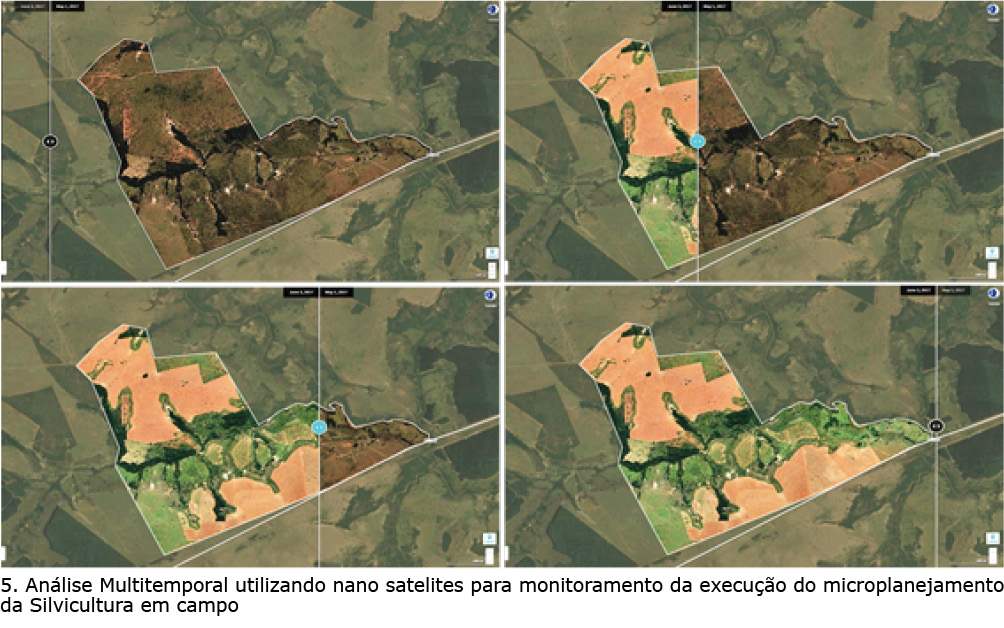

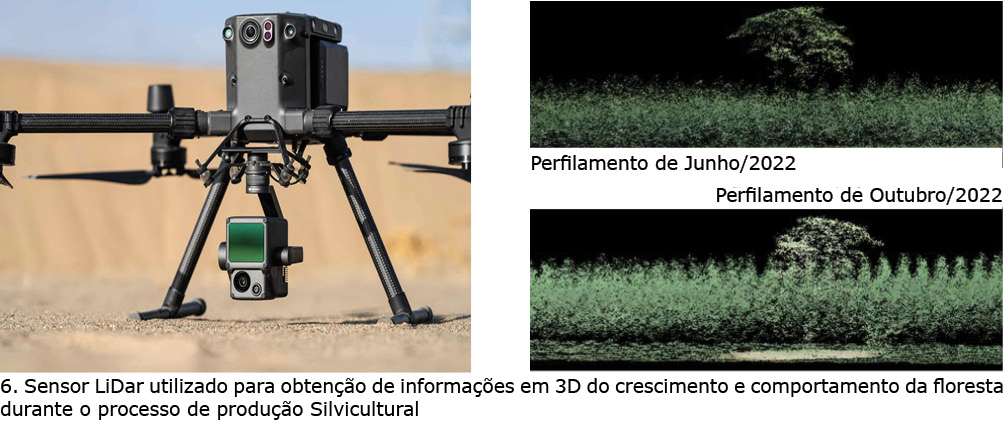

Esta mesma tecnologia satelital hoje é também empregada na detecção de matocompetição com o uso de imagens de alta resolução para cálculos dos índices de biomassa e detecção de plantas daninhas nos plantios florestais. Na parte do sensoriamento, praticamente já estamos na era das florestas 4.0, pois hoje quase todas as empresas já estão fazendo o uso de sensores inteligentes em seus povoamentos florestais para obtenção de informações de crescimento da floresta, e até mesmo o seu estado nutricional. A exemplo disso, temos os sensores LiDar que permitem um mapeamento em 3D – três dimensões, dos plantios florestais, fornecendo inclusive dados dendrológicos, permitindo modelagens do crescimento e da produção futura dos mesmo, conforme mostra o destaque da figura 6.

Ainda nessa mesma linha, temos os dendrômetros digitais que são sensores que medem o crescimento diariamente das árvores, permitindo a obtenção do comportamento das florestas em diferentes fases do seu estabelecimento, bem como o entendimento do efeito da sazonalidade das estações do ano no desenvolvimento da mesma, conforme apresenta o conjunto de fotos com os dispositivos IoT no conjunto 7.

O mais recente lançamento de mercado para esta prática de monitoramento contra incêndios em tempo real são os drones de longo alcance. Esses equipamentos possuem autonomia mínima de 6 horas de voo e com alcance mínimo de 60km do seu ponto de controle, o que permite uma mobilidade no patrulhamento das florestas pelo ar, na busca por qualquer ameaça que possa colocar em risco a produção florestal, tornando o processo silvicultural um dos mais seguros do mundo em termos de sinistralidade, conforme fotos do destaque de número 8.

São inúmeras as aplicações tecnológicas e inovadoras utilizadas nos processos silviculturais das empresas de base florestal, inclusive na parte de proteção dos seus ativos contra sinistros causados por fogo. Nesse campo, a tecnologia avançou imensamente com sistemas de monitoramento com câmeras de detecção automática de última geração que possuem o alcance mínimo de 15 km. Isto permitiu que o monitoramento seja realizado 24 horas ininterruptas, aumentando a segurança e a proteção dos povoamentos florestais, conforme demonstra o vídeo no destaque de número 9.

Praticamente, todas as operações silviculturais hoje permitem ser apontadas digitalmente, seja utilizando um equipamento mobile, tais como smartphones e tablets, e, até mesmo, com soluções embarcadas mais robustas, tais como computadores de bordos altamente inteligentes.

A diferença é que, para esse segundo, é possível a obtenção de forma automática dos ciclos operacionais de produção, bem como do estado de máquina, informações essas muito importantes para o monitoramento em tempo real das atividades operacionais e tomadas de decisão baseadas em dados do presente e, também, predizer alguma falha que por ventura poderá acontecer com o equipamento em nível mecânico. Veja detalhes na figura 4.

Outro ponto importante na prática silvicultural é o acompanhamento da evolução das operações em campo com base no que foi planejado no início. Para isso, hoje, é possível o emprego de tecnologias de análises multitemporais utilizando nano satélites. Isso permite o controle do realizado versus planejado, de forma segura e inteligente para obtenção da assertividade e acurácia na definição e na execução do microplanejamento operacional, conforme demonstra o conjunto de imagens da figura 5.

Esta mesma tecnologia satelital hoje é também empregada na detecção de matocompetição com o uso de imagens de alta resolução para cálculos dos índices de biomassa e detecção de plantas daninhas nos plantios florestais. Na parte do sensoriamento, praticamente já estamos na era das florestas 4.0, pois hoje quase todas as empresas já estão fazendo o uso de sensores inteligentes em seus povoamentos florestais para obtenção de informações de crescimento da floresta, e até mesmo o seu estado nutricional. A exemplo disso, temos os sensores LiDar que permitem um mapeamento em 3D – três dimensões, dos plantios florestais, fornecendo inclusive dados dendrológicos, permitindo modelagens do crescimento e da produção futura dos mesmo, conforme mostra o destaque da figura 6.

Ainda nessa mesma linha, temos os dendrômetros digitais que são sensores que medem o crescimento diariamente das árvores, permitindo a obtenção do comportamento das florestas em diferentes fases do seu estabelecimento, bem como o entendimento do efeito da sazonalidade das estações do ano no desenvolvimento da mesma, conforme apresenta o conjunto de fotos com os dispositivos IoT no conjunto 7.

O mais recente lançamento de mercado para esta prática de monitoramento contra incêndios em tempo real são os drones de longo alcance. Esses equipamentos possuem autonomia mínima de 6 horas de voo e com alcance mínimo de 60km do seu ponto de controle, o que permite uma mobilidade no patrulhamento das florestas pelo ar, na busca por qualquer ameaça que possa colocar em risco a produção florestal, tornando o processo silvicultural um dos mais seguros do mundo em termos de sinistralidade, conforme fotos do destaque de número 8.

São inúmeras as aplicações tecnológicas e inovadoras utilizadas nos processos silviculturais das empresas de base florestal, inclusive na parte de proteção dos seus ativos contra sinistros causados por fogo. Nesse campo, a tecnologia avançou imensamente com sistemas de monitoramento com câmeras de detecção automática de última geração que possuem o alcance mínimo de 15 km. Isto permitiu que o monitoramento seja realizado 24 horas ininterruptas, aumentando a segurança e a proteção dos povoamentos florestais, conforme demonstra o vídeo no destaque de número 9.

Por fim, é importante ressaltar que todo o processo de transformação digital de parte da cadeia de produção florestal somente poderá ter sucesso com os devidos envolvimentos e participação das pessoas que o conduzem, pois elas são os atores chaves para que as tecnologias e inovações adotadas tenham aderência e aceitação do meio, permitindo, assim, uma melhoria contínua das atividades e operações silviculturais realizadas.