Reginaldo Gonçalves Mafia

Gerente de Tecnologia de Manejo Florestal da Suzano

OpCP71

A qualidade do plantio como alavanca para aumento da produtividade

Estamos vivenciando mais um ciclo de baixa oferta de madeira. Por outro lado, a demanda deverá aumentar nos próximos anos, considerando os novos projetos de fábricas de celulose, sobretudo na região Centro-Oeste do Brasil. Para pressionar ainda mais o setor florestal, tem sido comum observar problemas de produtividade atrelados às variações do clima, o surgimento de novas pragas e doenças e a expansão dos plantios para regiões de menor conhecimento e com maiores desafios para atingir altas produtividades. Além da baixa oferta de madeira, outro fator preocupante é a baixa disponibilidade de terras, que, devido ao avanço mais acelerado da agricultura, tem limitado, cada vez mais, a expansão da base florestal.

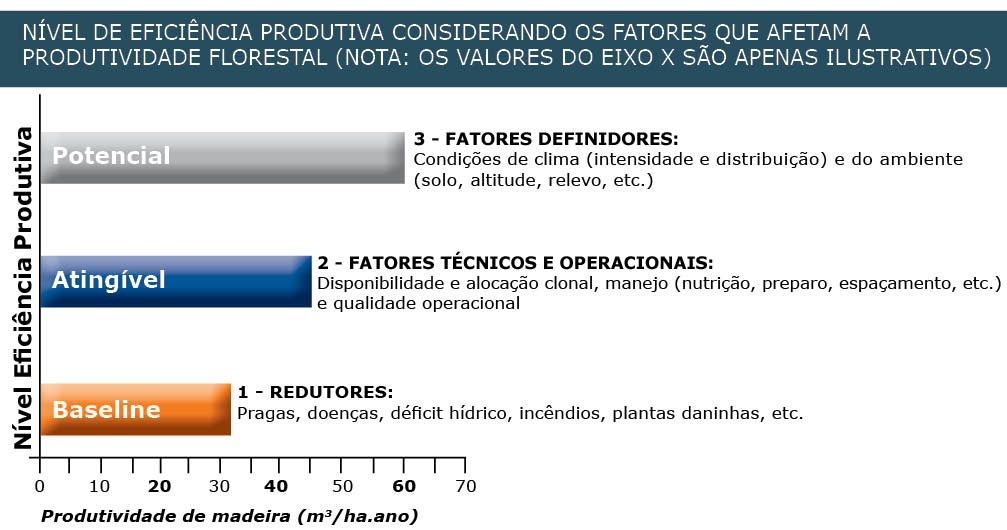

Considerando esses fatores de restrição, seja de aumento da base florestal ou das pressões do ambiente, cabe ressaltar a importância de atingir um alto nível de eficiência em produtividade florestal, o que depende de vários fatores, conforme figura em destaque.

Em geral, quando se buscam alternativas para o aumento da produtividade, normalmente aparecem duas vias principais de atuação. A primeira consiste nos produtos advindos dos programas de melhoramento genético, ou seja, novos clones e sua correta alocação, considerando a interação genótipo-ambiente.

A segunda alternativa consiste em buscar otimizar as recomendações de silvicultura e manejo, incluindo, principalmente, espaçamento de plantio, adubação, preparo de solo, controle de plantas daninhas, entre outros.

Todavia, a qualidade dos plantios, sobretudo na fase de formação florestal, complementa a tríade fundamental para alcançar e manter altas produtividades. Sabe-se que a baixa qualidade, nessa fase, pode comprometer os ganhos advindos das duas outras vias. Aqui, podemos entender formação florestal como sendo todas as atividades de planejamento, os insumos e os serviços necessários para realizar o preparo da área, plantio e manutenção até o segundo ano da floresta. Essa fase, ao ser bem executada, é fator-chave.

Existem basicamente duas formas de avaliar a qualidade na formação florestal. A primeira é indireta e consiste em avaliações da qualidade dos insumos e das atividades operacionais. Partindo do princípio de que as recomendações técnicas estão adequadas e ajustadas às condições de plantio e cultivo, podem-se empregar metodologias e gerenciar indicadores para dose, intensidade, momento de aplicação, entre outras variáveis que podem impactar a qualidade do plantio.

A outra forma consiste em avaliar, de forma direta, o produto, ou seja, o próprio plantio resultante. Nesse caso, parâmetros de uniformidade, crescimento e sanidade, entre outros, podem ser avaliados como medidas de aferição e ajustes nos controles de qualidade, bem como para estimar o potencial produtivo dos plantios.

Em geral, o impacto da baixa qualidade na formação florestal é subdimensionado e, muitas vezes, não é percebido. Existe uma vasta quantidade de resultados de pesquisa demonstrando o efeito isolado de fatores que impactam a qualidade e, por consequência, a produtividade florestal.

Mas, na prática, geralmente esses fatores atuam conjuntamente e são responsáveis pelas variações de produtividade, mesmo em condições uniformes de cultivo. Isso é facilmente avaliado quando se comparam informações de inventário a partir de extratos uniformes. Nessas situações, é comum observar grandes variações, mesmo se tratando de plantios de um mesmo material genético, em um ambiente de solo e clima uniformes e sob o mesmo manejo silvicultural. Nessas situações, pode-se inferir que parte dessa variação pode ser explicada por diferenças na qualidade das etapas de formação florestal.

Partindo do princípio de que a qualidade é fator-chave para atingir altas produtivas, o que limita a sua exploração em nível máximo na prática? Apesar de ciente da sua importância e da existência de várias ferramentas para avaliação, monitoramento e gestão, como a produção de madeira é um processo complexo, vários fatores acabam influenciando. Notadamente, esses fatores atuam mais fortemente em situações atípicas.

Apenas como um exemplo disso, em grandes projetos de expansão florestal, em novas regiões, as limitações têm início com a baixa oferta de mão de obra, especialmente qualificada, seja para contratação, seja de prestadores de serviços. Adicionalmente, nessas situações, ocorre limitação na oferta de mudas de boa qualidade, clones adaptados, entre outros insumos essenciais. O somatório desses e outros fatores acaba limitando o atingimento de alto padrão de qualidade.

Para finalizar, logicamente é fundamental investir em melhorias de processo, aumento da granularidade das informações e da precisão das recomendações no uso da inteligência artificial, bem como em inovações tecnológicas para aumentar a produtividade florestal. Mas, sem garantir a qualidade na execução, praticamente os ganhos advindos dessas iniciativas não são aproveitados na prática.