César Gomes Vieira

Coordenador de Silvicultura da Irani

OpCP71

O uso de imagens aéreas

O uso de novas tecnologias já é uma realidade, e a correlação dos dados de sobrevoo de drone com dados do controle de qualidade constitui uma importante ferramenta para auxílio na tomada de decisão e representa uma evolução no sistema de qualidade convencional.

O nascimento do controle de qualidade remonta ao século XVII, quando se buscavam formas de garantir os padrões de produtos manufaturados. Nessa época, o foco era a busca de produtos defeituosos e fora dos padrões aceitáveis, agindo de forma corretiva e não preventiva como a conhecemos. Desse modo, a ação que se tomava era a retirada dos produtos com defeitos. Isso implica perda de tempo e recursos produtivos, impacto financeiro, uma vez que se gastou para produzir tais produtos, e, claro, eficiência reduzida, sendo que, na maioria das vezes, ocorria retrabalho para repor os produtos problemáticos.

Com o aumento da produção em massa, começa a surgir o controle estatístico, com conceitos e análises por amostragem, ganhando força a ideia de que o controle de qualidade deveria ter contornos gerenciais e ser usado como diferenciação para ganhos de competividade, sendo usado como estratégia de diferenciação entre as empresas.

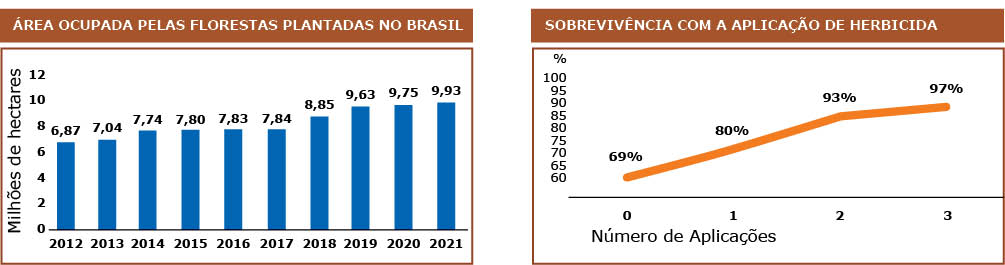

Mas o que tem a ver a área florestal com isso? Ora, como falado anteriormente, com a produção em massa, há necessidade de controlar a qualidade dos produtos/operações, e, nesse sentido, a área florestal se encaixa perfeitamente: em 9 anos, quase dobramos a área plantada; para ser mais preciso, aumentamos em 45%.

De acordo com a Ibá, a quantidade de árvores plantadas por dia chega a 1 milhão. Se considerarmos o início dos incentivos fiscais na década de 1970, passando de uma atividade rudimentar e pouco tecnificada, o setor de florestas plantadas alcança o status de importante atividade na balança comercial brasileira, lançando o País como um dos principais players do setor, atingindo recordes de produtividade e consolidando o Brasil como um dos países mais atrativos para se plantar florestas, com clima, solo e condições favoráveis ao crescimento.

Com a evolução da tecnologia e o mundo digital cada vez mais presente no dia a dia, a área florestal teve que se adaptar e inserir, na sua rotina, novos meios de tratar a massa de informações geradas provenientes das operações. Com isso, o termo floresta 4.0, bem como o conceito de digitalização dos processos e automação de boa parte das atividades, vem se transformando em realidade.

Quando se fala de mecanização, a gama de possibilidades e ferramentas disponíveis no mercado é imensa, porém, o grande sucesso nesse mundo, ou o ganho real, está em como transformar essa tecnologia em diferencial competitivo. Traduzir esse universo de variáveis e dados em informações que agreguem valor e tragam significado é o grande desafio no setor florestal.

Nesse sentido, o controle de qualidade tradicional, com lançamento de parcelas e tratamento de desvios, ganha ajuda com o auxílio de drones e imageamento. Tudo isso é importante, mas de nada serve se não há retorno com planos de ação bem definidos relacionados com a estratégia e percebidos como ferramenta importante de tomada de decisão pela área operacional.

Nesse ponto, vale uma ressalva em relação à indústria de pínus, cuja maior parte se localiza em regiões declivosas e, por consequência, ainda possui muitas atividades manuais, sobretudo na silvicultura (preparo de solo, plantio, tratos silviculturais), o que, por si só, incrementa a variabilidade nas operações.

Quando a atividade é mecanizada, é possível implementar sensores e monitorar diversos parâmetros, mas, quando a atividade é manual, essa tarefa se torna mais complexa e, na maioria das vezes, o fator humano influencia significativamente o resultado alcançado.

Ainda relacionado à cultura de pínus, o ciclo produtivo é mais longo. Ao passo que, n a cultura do eucalipto, a média é em torno de 7 anos, no pínus, estamos falando de 15 a 30 anos, e o controle de qualidade, via de regra, avalia uma janela de 30 a 45 dias pós-plantio. Essa avaliação é necessária para a programação de replantio, por exemplo. Contudo, quando se trata de ciclos tão longos, essa janela de avaliação, que é a mesma aplicada ao eucalipto, pode parecer prematura, ou até mesma precoce.

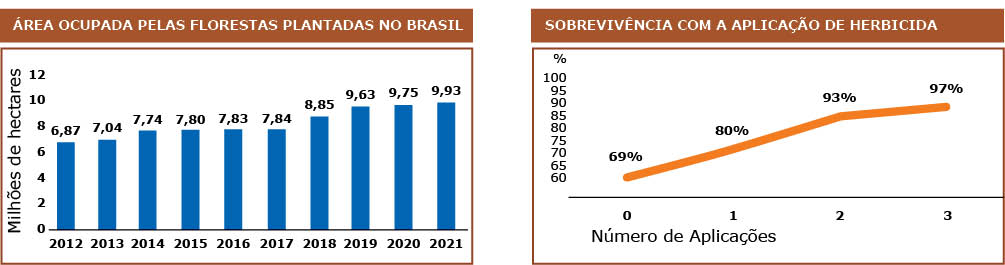

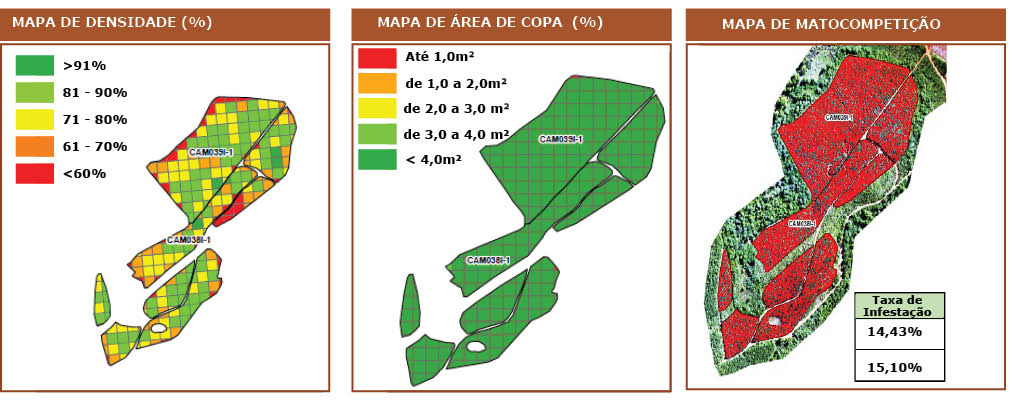

Nesse contexto, a análise de imagens torna-se uma aliada importante na gestão dos ativos florestais, passando de uma visão em parcelas para uma visão de todo o talhão, permitindo ao gestor identificar pontos que estão aquém dos indicadores e tomar ações de correção ou corrigir o plano de formação para futuras rotações.

O imageamento fornece informações importantes sobre a qualidade do povoamento como percentual de sobrevivência, vigor (m²/copa), infestação de matocompetição, e eles possuem correlação direta com os dados levantados no controle de qualidade convencional.

Outro ponto que está sendo estudado, e as imagens e os dados estão fornecendo subsídio, é com relação à mortalidade tardia, ou seja, pós o período de 45 dias preconizado para replantio, é possível identificar o quanto continuou a morrer, ou como será a tendência do povoamento até o final do ciclo, preservadas as condições fitossanitárias de pragas e incêndios. Esse resultado é obtido, em média, 1,5 ano após o plantio e serve como confirmação para as práticas silviculturas usadas, ou mostram o que deve ser melhorado ou corrigido nos ciclos futuros.

Nos casos em que é possível identificar falhas, todo um processo de investigação é iniciado, consultando as atividades realizadas no talhão e servindo para ajustes em futuras implantações. Esse tempo pós plantio é interessante, pois é um meio termo entre as avaliações de qualidade convencional (30 dias) e o tempo de ciclo total da cultura, fornecendo uma ideia qualitativa de como o povoamento está, pós-implantado.

Um exemplo prático obtido com essas informações e cruzando com os dados de manejo nos talhões sobrevoados está na aplicação de herbicida, em que se identificou que, com três aplicações pós-plantio, atingiu o melhor resultado de sobrevivência, devendo essa ser uma prática perseguida durante o ciclo da cultura.

Pensando no máximo uso de tecnologia, o ideal seria a substituição total do controle de qualidade convencional pelo imageamento, porém é necessário cautela, os algoritmos para identificação de sobrevivência em pínus conseguem identificar mudas somente após 1,5 ano de idade; esse é um ponto sensível, pois houve um grande avanço para identificação de mudas de eucalipto, sendo possível, até com 30 dias, realizar levantamento de sobrevivência.

Contudo, no pínus, isso ainda não é possível, devido ao crescimento mais lento da cultura. Os algoritmos ainda apresentam dificuldade de identificar mudas jovens, muitas vezes confundindo-as com vegetação local. Outro ponto que impossibilita a substituição total é o fato de ainda existirem parâmetros de qualidade que o imageamento não consegue capturar, como deriva de herbicida, profundidade de subsolagem, qualidade do coveamento, que são dependentes de avaliação in locu por pessoa capacitada.

A análise espacial, ou imageamento, ainda apresenta pontos de melhoria e avanços necessários, mas já constitui importante ferramenta que, correlacionada ao levantamento de qualidade tradicional, fornece subsídios importantes para a tomada de decisão, auxiliando o gestor e dando uma noção mais concreta sobre a qualidade do povoamento.