Jozébio Esteves Gomes

Eldorado Brasil's Competitiveness Coordinator and Forestry Projects

OpCP71

Quality in operational processes: from seedling to wood transport

Implementing competitive quality control in forest-based companies, without overly burdening the process, is a great challenge. Because the activities are distributed over thousands of hectares, with hundreds of employees working in more than one work shift in the various operations existing in the broad forestry production chain.

To overcome these challenges, the commitment of top leadership is necessary, in order to guarantee the engagement of all employees, the standardization and continuous improvement of all processes, reducing the incidence of errors and rework, alignment between the different areas, ensuring the quality of processes and products at all stages of the forestry production cycle, and auditing them through key performance indicators and efficient metrics, which allow monitoring the entire process, from seedlings to transport of the raw material produced, the wood.

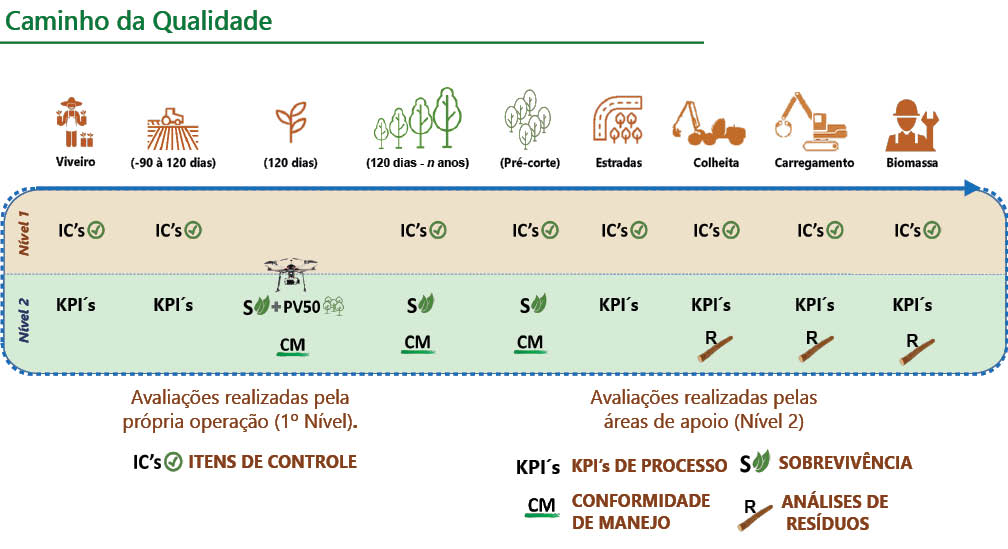

Companies in the forest-based sector have been developing several actions on different fronts to guarantee the quality of forest processes and products, from the production of seedlings to the wood delivered to the factory. Today, most companies have meticulously mapped processes and have quality assessments and audits at up to two levels, in all operations in the areas of forestry, harvesting, roads, loading and mechanical maintenance to monitor all their quality parameters.

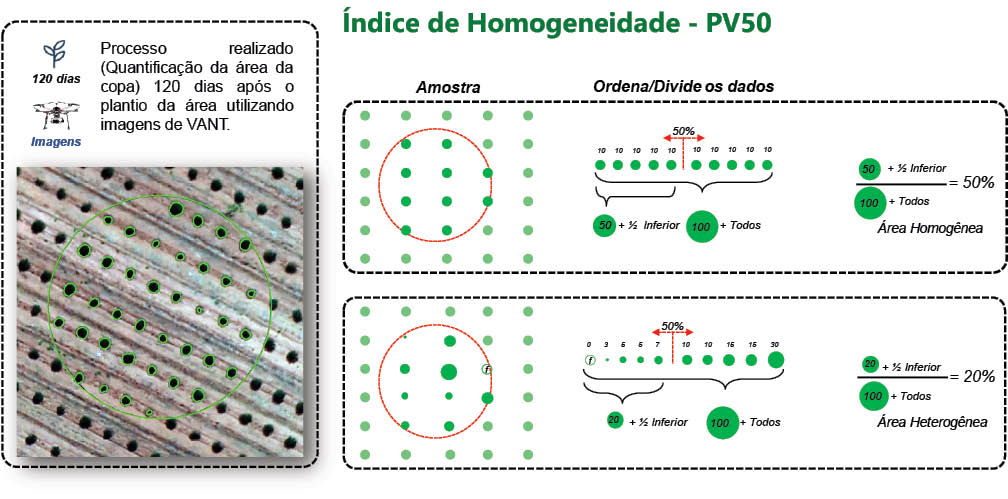

Generally, quality in companies in the forest-based sector begins in the nursery, during the seedling production process, where all phases of the plant production process are evaluated, from the collection of shoots to the load ready to be used dispatched for planting. In the field, the evaluation of the silviculture area usually starts with combating ants, controlling the cleaning of the area, followed by soil preparation, fertilization, seedlings, planting, irrigation, survival, replanting, occurrence of pests and weeds. Today, practically the majority of companies in the forest-based sector capture images of the area with drones after 120 days, in order to assess the survival and homogeneity of the areas.

In addition to this drone technology, the vast majority of companies have been employing the use of satellite images to monitor the occurrence of weeds up to 6 months. In this way, the final product of the silviculture area is quality forests, which continue to be monitored by the forest inventory teams, from 1.5 years until the time of cutting.

In the forest cutting and forwarding phase, in most companies in the forest base sector, it is expected that the harvest will deliver the area with piles located as pre-defined in the macro-planning and with adequate quality, that the wood will be in the right size, with the lowest percentage of husk and low silica contamination. For this purpose, the following items are generally monitored: tracing, debarking, delimbing, cutting, dirt in the wood, quality of the pile, location of the wood piles, height of the stumps and post-waste wood residues.

Also in the loading process of companies in the forest base sector, loading efficiency is monitored by measuring the loading time and the presence of unloaded wood at the stacking points. And the quality of the loads themselves. And, throughout the forestry process, the quality of the forest roads is monitored, through the quality of the drainage devices, the carriageway, the conservation of works of art (bridges, bushes and gates), the quality of the access to farms.

Practically, in all areas of the companies, forestry, harvesting, roads and loading, quality assessments of maintenance activities are carried out. And, in general, key performance indicators are monitored: controls, organization of the work environment, available and complete tools and adequate stock of parts. Usually, all these metrics, norms and guidelines on how to carry out quality monitoring, in the different areas of the companies, are made available through a documentation system and also in pocket guides, to facilitate the consumption of information by the operational areas.

It is important to highlight that, to ensure efficiency, without burdening the quality process, the assessments are carried out in a decentralized manner, with the involvement of all employees. For this, it is recommended the division into level one and level two, as previously mentioned. At level one, operational leaders self-assess their activities and are internally audited by level two. At level two, external audits are carried out by quality technicians specialized in each of the processes and forestry production. The results are usually consolidated in reports and presented to senior management, for dealings and decision-making that ensure the quality assurance of processes and products.

With so many areas and activities monitored in companies in the forestry sector, a lot of data is collected that needs to be transformed into information to assist in decisions.

With so many areas and activities monitored in companies in the forestry sector, a lot of data is collected that needs to be transformed into information to assist in decisions.

And, to facilitate this process, the implementation of digital technologies is fundamental to accelerate the obtaining and processing of quality data and information, as well as the automatic release in intelligent control panels for better consumption of information by the parties interested.

However, the success of the quality assessment processes of companies in the forest-based sector depends on people who are trained and competent in the assessment and audit models, with the aim of allowing that the commitment of deliveries is always evolving positively and contributing significantly to the results of companies.