Gustavo Henrique Rodrigues e Tais Moreli Cambahuva Rufino

Engenheiro de Inventário Florestal e Gerente de Performance e Monitoramento Florestal, da Bracell-SP, respectivamente

OpCP75

Uso de LiDAR embarcado em drones no inventário pré-corte

O crescimento do setor florestal e o uso intensivo da madeira torna os planejamentos de curto, médio e longo prazos de vital importância e exigem que eles sejam cada vez mais otimizados para garantir o fluxo de madeira ao longo do tempo. Dito isso, o monitoramento dos recursos florestais em larga escala é necessário e requer o emprego e a integração de técnicas de sensoriamento remoto e de amostragem florestal em campo.

O sensor LiDAR (Light Detection and Ranging) é uma tecnologia de ponta que pode ser utilizada em diferentes produtos, tais como: modelos digitais de terreno e modelos digitais de superfície. Normalmente é utilizado para levantamentos topográficos a fim de caracterizar estrutura e é cada vez mais aplicado para obtenção da volumetria no Inventário Florestal, tanto para florestas nativas, quanto para florestas plantadas.

A tecnologia é caracterizada como um sistema ativo de sensoriamento remoto. Seu funcionamento envolve a utilização de pulsos de laser direcionados ao solo e, através do tempo gasto para retorno destes pulsos se tem a estimativa, neste caso em específico, da altura da floresta. No geral, este tempo será processado para calcular as distâncias variáveis entre objetos, ou da superfície terrestre, tornando possível determinar formas, alturas, dentre outros, bem como revelar detalhes intricados da estrutura florestal que antes permaneciam ocultos nos métodos tradicionais de inventário.

Essa riqueza de dados não só aprimora o planejamento e a execução das práticas de manejo sustentável, mas também impulsiona a eficiência de operações florestais que por vezes apresentam um alto custo agregado.

Outro grande diferencial é que para imagens derivadas de sensores passivos a grande limitação é que podem ser obtidas informações bidimensionais das florestas. Já no caso dos sensores ativos, onde está enquadrado, temos a condição de gerar imagens tridimensionais, possibilitando fornecer, além dos cálculos de área, também as características da estrutura vertical da vegetação amostrada.

Comparado aos métodos tradicionais, o LiDAR se destaca pela eficiência operacional, pela capacidade de cobrir grandes áreas rapidamente e fornecer dados mais abrangentes e precisos. Este avanço representa uma mudança paradigmática, possibilitando transitar de estimativas por amostragem para avaliações quase censitárias das florestas, com identificação de variações intraparcelas que eram previamente inacessíveis.

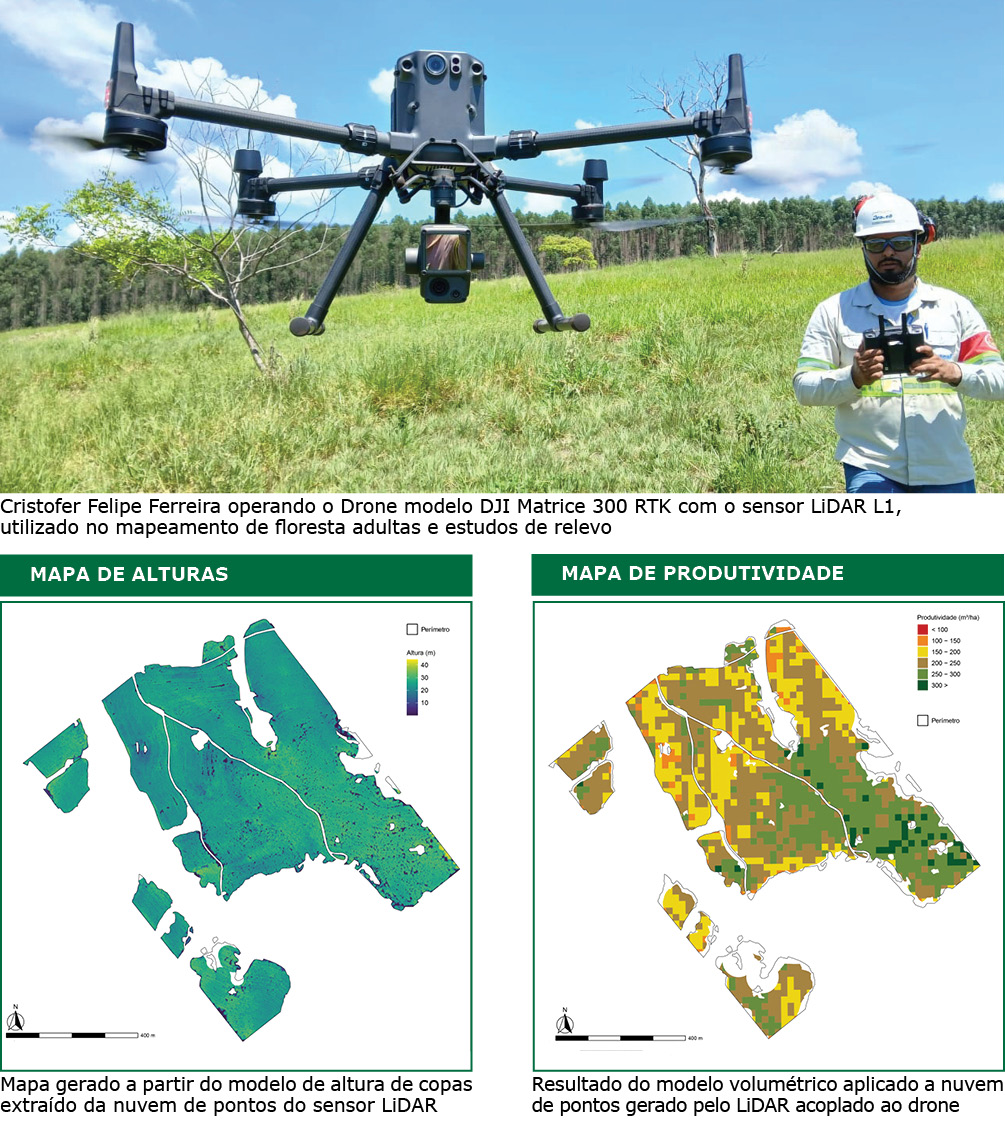

A Bracell vem empregando essa tecnologia embarcada em drones para a obtenção do Inventário Pré-corte melhorando a estimativa de volume que será colhido e posteriormente entregue na fábrica. A ideia de utilizar esta tecnologia vem da alta intensidade amostral, uma vez que ao passar no inventário contínuo de uma parcela a cada 10 hectares, o inventário Pré-corte exige uma parcela a cada 3 hectares, triplicando os custos da coleta de dados.

A adoção do uso de drones equipados com esses sensores tem sido um diferencial, pois proporciona uma maior flexibilidade e uma resolução de dados extremamente alta, que não apenas agiliza a coleta de dados em superfícies extensas como também viabiliza a geração de subprodutos valiosos para as mais diversas áreas florestais, como mapas de produtividade e modelos detalhados de copas de árvores que podem, inclusive, serem utilizados para o mapeamento de clareiras e falhas de plantio.

Com isso, deixamos de utilizar valores médios, como volume o individual (VMI), e passamos a utilizar estratos dentro do talhão, melhorando não apenas a acurácia na informação de volume de madeira, mas passamos a ter uma nova estratégia na colheita aperfeiçoando o planejamento de produtividade por estrato de volume.

Entretanto, apesar de sua indiscutível eficácia, o LiDAR não elimina a necessidade de métodos tradicionais de amostragem - a calibração dos modelos matemáticos, frequentemente embasados em técnicas de aprendizado de máquina, requer dados de campo precisos para garantir a acurácia das estimativas geradas.

Assim, a complementaridade entre os métodos é essencial para o aprimoramento contínuo dos modelos empregados no inventário florestal. Além disso, cabe destacar que, apesar dos benefícios, as nuvens de pontos acabam resultando em processamentos pesados e demorados que necessitam de certos investimentos tecnológicos.

O projeto piloto foi iniciado em 2022 em parceria com a APRIL, empresa de celulose e papel do Grupo RGE do qual a Bracell também faz parte. Através do conhecimento técnico dos nossos “irmãos” da Indonésia iniciamos o projeto com alguns modelos por eles aplicados para a floresta de eucalipto que posteriormente foram adequados para o nosso perfil de floresta, reduzindo o tempo de teste e melhorando o aproveitamento dos recursos tecnológicos.

Para garantir o sucesso da ferramenta são necessários o domínio de 3 etapas principais:

a) O Voo: no projeto piloto foram realizados voos com o equipamento LiDAR acoplado em avião agrícola e em drones. A Bracell escolheu usar o LiDAR acoplado em drone por dois principais motivos: 1º pela autonomia no plano de voo, uma vez que temos a equipe própria para pilotar os drones; 2º e mais importante, pela qualidade da nuvem de pontos que permite extrair métricas mais precisas para o modelo volumétrico – contamos com o time de Topografia da Bracell para realizar os voos de Drones;

b) O Processamento: foi necessário investir em hardware e armazenamento para receber uma quantidade enorme de dados para processar, além do uso de IA (Inteligência Artificial)para dar agilidade no processamento. Essa etapa fica com o time de Sensoriamento Remoto que tem toda a expertise para manusear as nuvens de dados e extrair as métricas, e

c) A Modelagem matemática: no que se refere à modelagem, um outro grande diferencial é que saímos da abordagem estritamente dendrométrica de equações com duas ou três variáveis para modelos robustos e sensíveis, nos quais um número relativamente alto de variáveis são empregados, como por exemplo: percentis de altura, densidade de copas, contagens de indivíduos, índices calculados por RGB, etc.

c) A Modelagem matemática: no que se refere à modelagem, um outro grande diferencial é que saímos da abordagem estritamente dendrométrica de equações com duas ou três variáveis para modelos robustos e sensíveis, nos quais um número relativamente alto de variáveis são empregados, como por exemplo: percentis de altura, densidade de copas, contagens de indivíduos, índices calculados por RGB, etc.

Finalmente essa última etapa é de responsabilidade do time de Inventário Florestal que realiza a modelagem e o cruzamento de dados com o inventário contínuo para disponibilizar o volume por talhões e os mapas com os estrados de produtividade.

Assim o LiDAR, na Bracell, passa por várias áreas até que o produto chegue para os times de Microplanejamento e Operação Florestal, indo ao encontro com os valores da empresa de times que se complementam e cliente. Além do volume de madeira e mapas de produtividade, a tecnologia LiDAR vem sendo empregada em outros produtos na Bracell, como:

• Mapas de declividade para as operações de corte e baldeio;

• Mapas de superfície do solo para a análise hídrica e recomendação de curvas de níveis e terraços para conservação do solo, e

• Mapeamento de rede elétrica e outras benfeitorias, dentre outros.

Em resumo, o LiDAR tem se estabelecido como uma ferramenta transformadora no Inventário Florestal, contribuindo significativamente para a precisão, eficiência e sustentabilidade do manejo das florestas plantadas no Brasil. A integração dessa tecnologia com práticas tradicionais e a superação de seus desafios operacionais apontam para um futuro ainda mais promissor no setor florestal brasileiro.