Lonard Scofield dos Santos

Diretor da Master Solução Florestal

OpCP72

O mais importante é ter um sistema para “chamar de seu”

Sinto-me honrado com o convite da prestigiosa Revista Opiniões para escrever sobre o panorama mundial dos sistemas de colheita. Entretanto, escrever sobre esse tema não é uma tarefa fácil, pois esta publicação tem sua distribuição dirigida a todo o sistema florestal brasileiro, o qual, felizmente, é repleto de profissionais que são especialistas mundialmente reconhecidos em colheita florestal. Portanto, ler sobre colheita com harvester ou com feller, para um público tão seleto, pode ser enfadonho, de tão óbvio que lhe possa parecer.

No meu conceito, o panorama mundial dos sistemas de colheita converge em sua grande maioria para os dois principais sistemas de colheita: O Cut to length (sistema de produção de toras curtas) e o Full tree ou Tree length (sistema de colheita da árvore inteira).

Apresento meus comentários sobre o panorama mundial dos sistemas de colheita e uma breve análise da maioria dos sistemas de colheita conhecidos por mim. É importante ressaltar que quando se olha e analisa um determinado sistema de colheita pela primeira e única vez, pode-se concluir que o sistema é falho. Porém quem vivencia sua própria colheita no dia a dia, ficará convicto de que aquele sistema o atende plenamente.

É imensa a amplitude dos sistemas de colheita, obviamente em função da enorme diversidade de topografia, tipo de solo, espécie reflorestada, volume mensal de colheita, destino da madeira, VMI, condições climáticas, oferta e qualificação de mão de obra, centros de treinamento, capacidade de investimento, infraestrutura, malha viária, etc. Com tamanha diversidade, as empresas obrigam-se a adotar sistema próprio e único de colheita.

De maneira geral, temos dois sistemas principais de colheita florestal mecanizada:

O sistema C-T-L (Cut-To-Length), que pode ser composto por:

Harvester sobre pneus ou esteiras;

Escavadeira hidráulica com cabeçote harvester;

Forwarder;

Trator agrícola autocarregável com grua.

E o sistema TL (Tree Length) ou FT (Full Tree). Esse sistema pode ser composto por feller buncher sobre pneus ou esteiras.

Escavadeira com cabeçote feller com disco ou cabeçote feller direcional;

Skidder 4x4 ou 6x6;

Skidder clam-bunk;

Mini skidder.

C-T-L: FROM HORSE TO HARVESTER - do cavalo à colhetadeira:

Essa expressão foi criada pela diretoria florestal de uma empresa sueca, a qual liderou e financiou grande parte do desenvolvimento de máquinas, equipamentos e sistemas de colheita, para exprimir o real significado do rápido avanço da mecanização das atividades de colheita, permitindo, assim, passar do cavalo (os quais eram e ainda são realmente utilizados) para o harvester em pouco mais de 35-40 anos. Obviamente o cavalo era usado para remoção/transporte das toras e não na colheita/harvester. Mas a expressão pode claramente indicar o efeito da mecanização. O desenvolvimento do Sistema CTL ocorreu na Escandinávia no início da década de 60. E a partir de 1985-1990, a grande maioria da colheita florestal na Escandinávia já era feita com harvesters.

O sistema CTL produz toretes entre 2,0 e 8,0m. No Brasil tivemos a oportunidade de passar a usar, ainda que com grande tropicalização para uso no eucalipto, os harvesters que já haviam sido duramente desenvolvidos na Escandinávia, a partir de 1995-2000. Ou seja, apenas 15 anos após o surgimento da tecnologia.

Como estamos atualmente? Felizmente no mesmo nível tecnológico existente na Escandinávia. Máquinas e equipamentos que saem das fábricas hoje com destino a Europa, USA, Escandinávia, são exatamente as mesmas que chegam ao Brasil. Há pouca diferença ainda somente em relação ao sistema de telemetria devido às condições de cobertura 4G/5G no Brasil.

Sistema de colheita de árvores inteiras: TL/FT: FROM IRON MULE TO SKIDDER:

Sistema de colheita de árvores inteiras: TL/FT: FROM IRON MULE TO SKIDDER:

O desenvolvimento do arraste mecanizado foi iniciado na década de 1920, tendo chegado ao conceito do skidder atual já em 1970. Ou seja, ele tem uma história mais antiga de desenvolvimento do que os harvesters e forwarders. O sistema TL/FT é considerado de tecnologia mais simples (menos eletrônica) do que as máquinas do sistema CTL. Além disso, é considerado mais robusto e mais produtivo individualmente do que as máquinas CTL.

Obviamente a escolha do sistema não leva em conta somente robustez e maior produtividade por máquina individualmente, mas, sim, todas as etapas produtivas do sistema de colheita em si. É notado que o sistema CTL representa no Brasil maior volume de colheita, enquanto a totalidade do sistema FT/TL usa as máquinas originais desse sistema, porém para produzir toras curtas (toras CTL), seja com cabeçote processador após o arraste ou seja com o uso de garra traçadora.

Existem ainda inúmeros outros sistemas que podem também ser combinados:

Torre de arraste;

Torre de arraste e com cabeçote processador;

Máquinas com guincho auxiliar de tração;

Guinchos de tração autopropelidos;

Motosserra;

Desgalhador -pull thru delimber;

Desgalhador por impacto – stroke delimber.

Certamente, os próximos passos em termos de sistemas de colheita passarão pelo aprimoramento dos sistemas de monitoramento das máquinas a distância: manutenção, controle de produção, manutenção preditiva, performance do operador, etc. E em futuro muito próximo, teremos o surgimento das máquinas autônomas.

Certamente, os próximos passos em termos de sistemas de colheita passarão pelo aprimoramento dos sistemas de monitoramento das máquinas a distância: manutenção, controle de produção, manutenção preditiva, performance do operador, etc. E em futuro muito próximo, teremos o surgimento das máquinas autônomas.

O forwarder é um candidato ideal para se transformar em máquina autônoma, a exemplo dos caminhões autônomos já em operação na mineração. Com a globalização e a presença no Brasil da grande maioria dos fabricantes de máquinas e equipamentos florestais, o intercâmbio de sistemas e o acesso às tecnologias existentes ocorrerão de forma imediata, proporcionando às empresas florestais a possibilidade de uso de qualquer sistema de colheita que esteja sendo utilizado em condições operacionais similares.

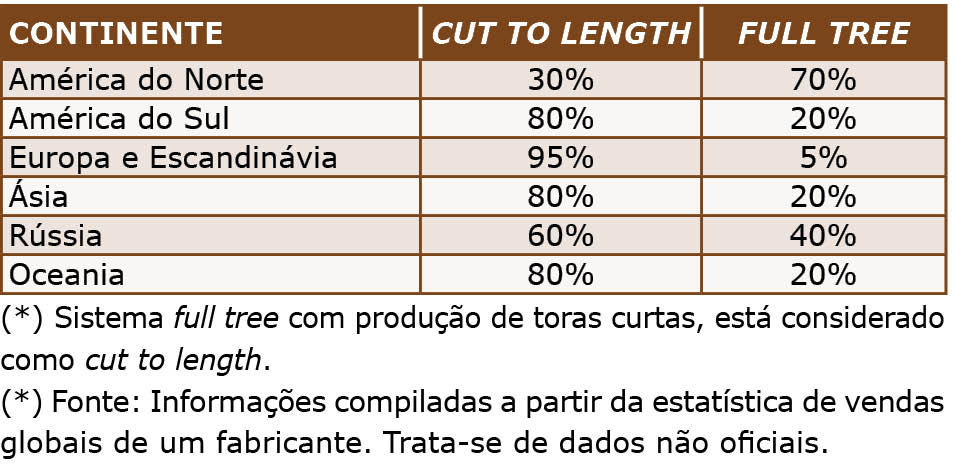

Desconheço a existência de dados estatísticos atualizados sobre a distribuição percentual de uso de cada sistema de colheita. A maioria dos dados estatísticos são de 3 a 4 anos atrás, mas é comumente aceito que o sistema de tora curta (CTL) é dominante em termos de volume de colheita no mundo todo.

Devido ao enorme crescimento da indústria de celulose na América Latina, com operação em área plana, uma só espécie, e descascamento no campo, o sistema cut to length representa cada vez mais em termos de volume de colheita.

De forma geral, podemos resumir o panorama mundial dos sistemas de colheita conforme a tabela abaixo: Concluo esse artigo afirmando que, independentemente de globalização, tecnologia, tendências e outros fatores, o mais importante é ter um sistema para “chamar de seu”. O que interessa é se o sistema atende os objetivos de custo/m³, segurança e garantia de abastecimento de matéria prima exigidos pela empresa.

Árvore inteira ou sistema de colheita de árvores inteiras:

Árvore inteira ou sistema de colheita de árvores inteiras: